Commercial operations in Rwanda prove the company can deliver emergency blood packs in minutes, rather than hours

Rwanda is known as the land of a thousand hills, and our car seems to go over every one of them as we drive from the small town of Muhanga to the even smaller town of Kinazi. The 50-kilometer trip into western Rwanda will take us well over an hour. We’re on our way to rendezvous with a blood-carrying drone that will make the trip in under 14 minutes.

The drone is operated by Zipline, a California-based company focused on delivering medical supplies in areas with poor infrastructure. And not long after we arrive at Kinazi’s hospital, the fixed-wing drone materializes out of the blue. In a blink-and-you’ll-miss-it moment, the drone descends, opens a set of doors in its belly, and drops a small package that parachutes to the ground. The drone immediately begins to climb and vanishes over the hills as a staff member crosses the hospital parking lot to pick up the package—a shipment of blood ordered by WhatsApp less than half an hour earlier.

We then climb back into our car to start our bone-jarring return drive to Muhanga, one of Zipline’s launch sites, winding our way over dirt roads. By the time we make it back, the drone is flying smoothly toward another hospital elsewhere in Rwanda, with a fresh package of blood in its belly.

Delivery by drone is a futuristic idea that has caught the public’s imagination, and there are plenty of attempts to turn it into a commercial reality. Amazon, Google, and Domino’s Pizza have all pulled off carefully controlled demonstrations and pilot projects, delivering items such as sunscreen, burritos, and (of course) pizza to backyards and fields. But the world is waiting to see whether any company can find a business model that makes drone delivery a sustainable and profitable endeavor.

The answer may be here in Rwanda, where Zipline is delivering blood to 25 hospitals and clinics across the country every day. Zipline is betting that transporting lifesaving medical supplies, which are often lightweight and urgently needed, will be the killer app for delivery drones.

We visited Zipline’s Rwanda operations to understand the technical challenges of building a drone-based delivery service. We found obsessively engineered drones that the company has optimized for blood delivery, along with a detailed plan for integrating them into the country’s medical system. Zipline’s methods could be a model for Africa, as the company’s founders expand their drone services into other countries on the continent this year. But despite the company’s technological and logistical successes thus far, Zipline still has to prove that it can scale up its operations—that it can go big enough to match its soaring ambitions.

Rwanda has modernized rapidly since the 1990s, when the country began its recovery from civil war and genocide. The change has been remarkable: Since 2000, the percentage of the population living below the poverty line has dropped from 59 to 39 percent, and life expectancy has increased by nearly 20 years. The government’s Vision 2020 national development plan emphasizes technology infrastructure, and fiber-optic cables now run alongside main roads. More than 95 percent of the population is covered by 4G cellular networks.

The government has also invested heavily in health care. But its push to construct hospitals and clinics has resulted in some shiny new medical facilities opening their doors to patients before the roads leading to them have been improved. Traffic is slow on the two-lane highways that twist around the hills, while the roads that branch off toward small towns soon turn into dirt.

For hospitals in need of critical medical supplies, Rwanda’s roads pose a real problem. Hospital administrators worry most about blood and blood products, which have a short shelf life and strict storage requirements. It’s also difficult to predict how many packs of each blood type will be needed at a given facility, and when. In an emergency, it can take up to 5 hours for a Rwandan hospital to receive a blood delivery via road, which could easily mean death for a patient in need.

Three entrepreneurs—William Hetzler, Keller Rinaudo, and Keenan Wyrobeck—founded Zipline in 2014 with the goal of solving such problems through on-demand deliveries by drone. Rwanda was the ideal test bed, with its challenging terrain, relatively small size (about the same area as the U.S. state of Maryland), extensive wireless connectivity, and receptive government.

Outside observers are cautiously optimistic about the company’s efforts so far. “I like Zipline’s approach in Rwanda—they’re operating commercially, which is more than most drone delivery companies [are doing],” says Adam Klaptocz, cofounder and CEO of Rigitech, a Swiss startup that’s using small cargo drones to connect rural communities in the developing world. “They’re not trying to be the solution for all drone deliveries,” says Klaptocz. “But they’re doing this, and it seems like they’re doing it better than the existing way.”

Zipline has two fulfillment centers in Rwanda, which it refers to as “nests.” The Muhanga nest, which we visited, is about 50 km from the capital of Kigali, and a 2-hour drive, thanks to lumbering trucks that clog the main roads. Its small cluster of buildings abuts a maize field, and the locals who work the field grudgingly move out of the way whenever a drone passes low overhead.

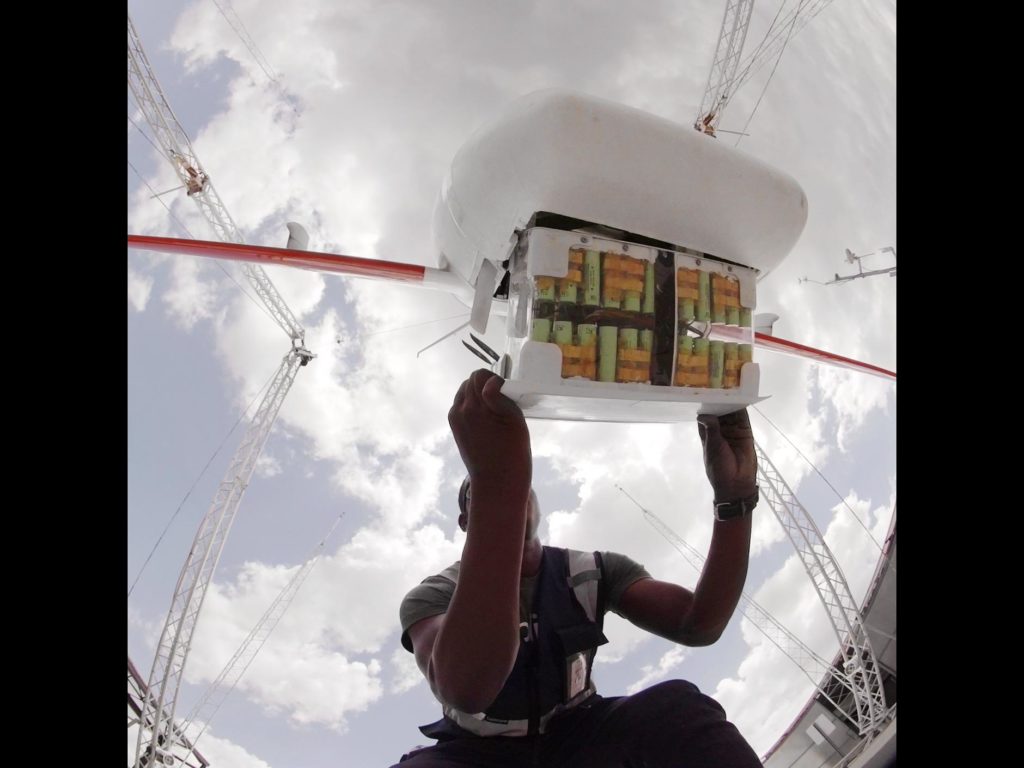

Several times a week, blood and blood products arrive here by truck. When one shipment arrives during our visit, Israel Bimpe, Zipline’s head of national implementation, turns to us with a smile, saying: “The blood is here!” Workers spring into action, transferring the packs of whole blood, plasma, and platelets into refrigerators. When an order comes in from a hospital via phone, website, WhatsApp, or SMS, a worker wraps the needed packs in padding and stuffs the bundle into a bright red box, which has a wax-paper parachute attached.

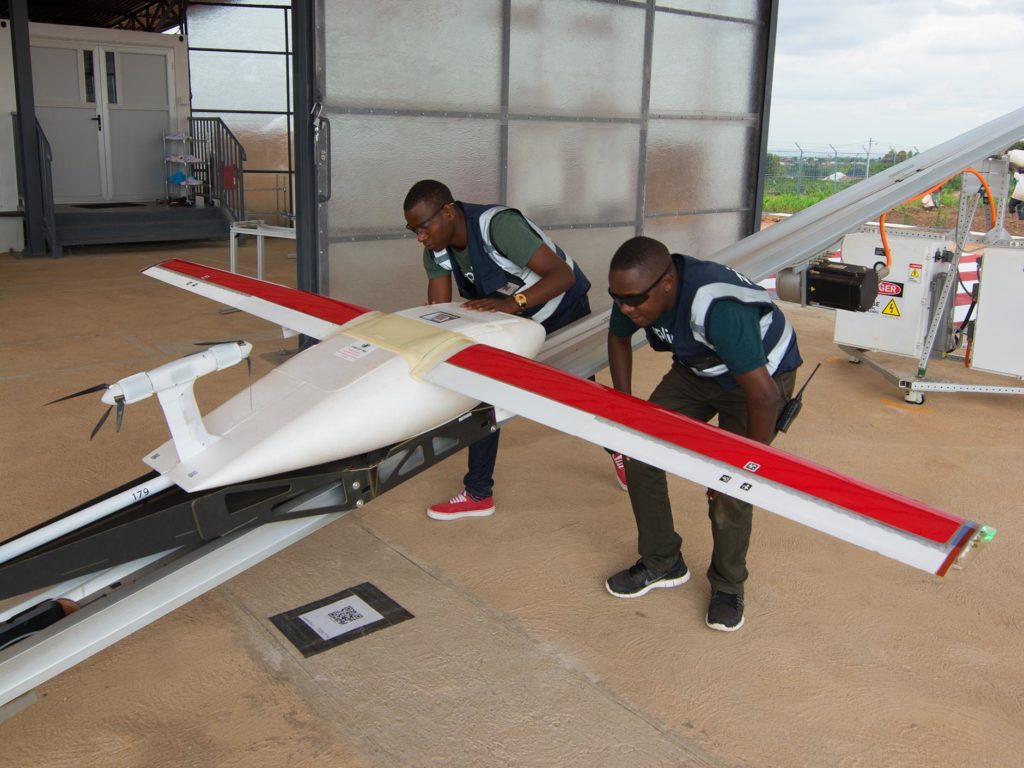

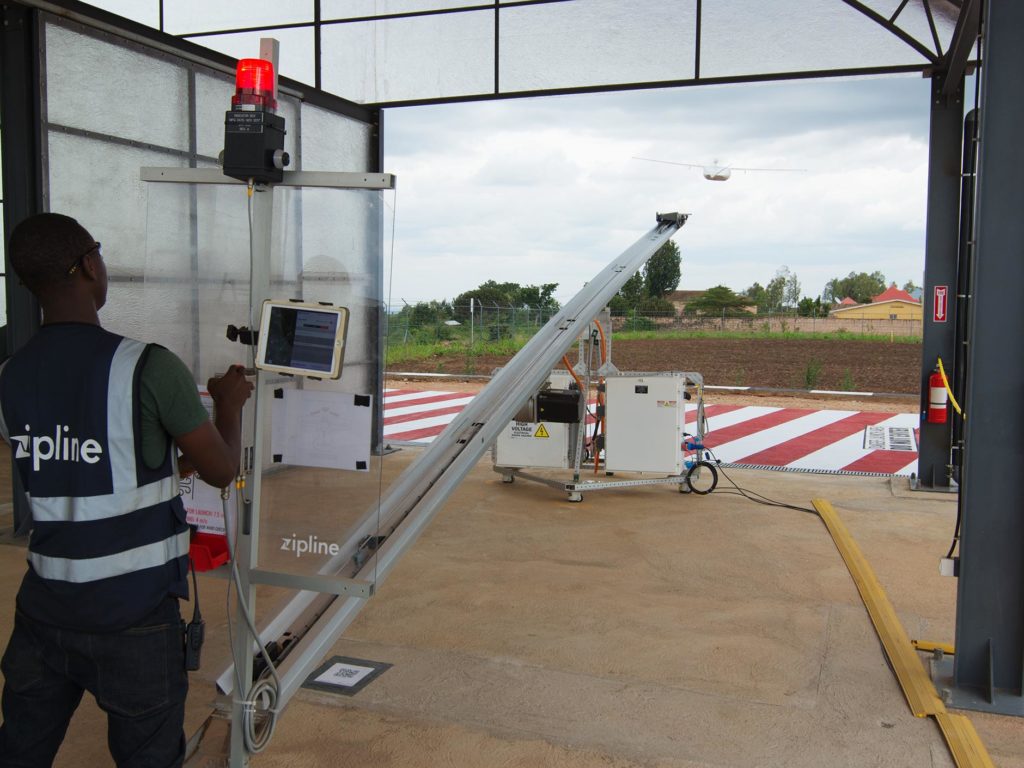

A technician places the box and parachute in the belly of a drone behind a spring-loaded hatch, then snaps a modular battery pack into the drone’s nose. Two people carry the drone to a 13-meter-long electric catapult powered by a bank of supercapacitors, then run through a preflight checklist with the aid of a smartphone app. Zipline confirms the drone’s flight plan with the Rwanda Civil Aviation Authority and requests flight clearance, while the company’s technicians do their best to convince enthusiastic local kids to move a safe distance away from the launch. Finally, with a satisfying zzzing, the catapult flings the drone skyward, accelerating it to 100 kilometers per hour in half a second. It swiftly rises over the Rwandan countryside to a cruising altitude of 120 meters. It’s a dramatic moment—and at Muhanga it happens 20 to 30 times a day.

As soon as a drone—which the company calls a Zip—leaves the catapult, it’s fully autonomous. While both Zipline and the Rwanda Civil Aviation Authority track the aircraft and can redirect it at any time, in practice the Zips are mostly forgotten about until they return home, mission complete. In the air, each Zip follows a predetermined flight plan, relaying data on its position and status through Rwanda’s wireless network.

Our visit to the Kinazi hospital, one of the closer delivery sites, shows us the other end of a Zip’s journey. About 5 minutes before the drone arrives, hospital staff members get an automatic text alert telling them to send someone outside to await the delivery. At Kinazi, that means waiting at the edge of a small grassy field adjacent to the hospital’s parking lot. During our visit, the staff member arrives only after the drone has dropped its package, which just goes to show that blood delivery by drone isn’t the least bit exciting in Rwanda anymore.

Zips can carry relatively large payloads long distances because they’re fixed-wing aircraft, which are significantly more aerodynamically efficient than rotorcraft (such as today’s common quadcopters). Launching a fixed-wing drone from a catapult is easy, but landing it safely—without landing gear or a lengthy runway—is a challenge. Zipline’s solution is a recovery system that the team affectionately refers to as Tall Bob. Its two 10-meter-high towers each have a vertically mounted rotating arm, and a cable is strung between the arms. As a returning Zip flies between these two towers, the arms rotate upward, in a fraction of a second, to snag the cable on a tiny metal hook below the Zip’s tail. The drone is pulled to a stop within a few meters, then the arms allow the drone to swing down and back between the towers. In principle, it’s similar to the way planes land on aircraft carriers.

To reset the system, workers simply lift the Zip off the wire at ground level, and then rotate the arms back up to prepare for the next capture. The Zipline team has grown accustomed to the remarkable precision of its drone-capturing system, but during our visit we never get tired of seeing the wire pluck Zips out of the sky.

While Zips can’t launch when crosswinds are too intense, they can handle both high winds and rain once they’re airborne, so weather-related delays at the launch site tend to be brief. But the system isn’t flawless: Zips will turn around if strong head winds drain too much of their battery power, and despite dual motors and redundant ailerons for flight control, mechanical failures do sometimes happen. If the Zip can’t make it back to the nest, it can autonomously deploy a parachute to bring itself gently to the ground. Zipline estimates that the emergency parachute deploys in around one in a thousand flights.

With dozens of orders coming in every day, Zipline needs to be sure that it always has drones ready to fly. So its engineers designed the Zips to be as modular as possible, allowing technicians to easily detach different pieces for repairs. While such repairs are common, particularly on the strain-bearing wings, there are always more than enough components to snap together into a fully assembled drone. A bank of chargers ensures that a charged battery pack is always ready to be slotted into a drone being prepped for launch.

The Zipline facility in Muhanga takes, on average, 10 minutes to launch an order. But Zipline’s engineers think that’s 9 minutes too long. Bimpe says that incremental changes to the process will eventually enable them to fulfill an order in less than 60 seconds. “We just need to improve it a bit more,” he says. “It’s tweaking operational procedures and improving software to reduce that time to 1 minute. We receive an order and as soon as we finish packing, we just put it on the Zip and it’s ready to go.”

Expected improvements in the Zips themselves will boost range: Today, the farthest hospital that Zipline delivers to is Butaro District Hospital, about 80 km away (45 minutes as the Zip flies). Because weight determines how long and how far a drone can fly, Zipline’s engineers are always looking for ways to lighten the load. Much of the focus is on the battery, which is the heaviest component of the aircraft. “We fight super, super hard to shave off grams,” says Michael Newhouse, Zipline’s battery lead. The Zipline team uses the smallest-gauge wires they can get away with and special wire strippers to remove excess insulation, thus saving fractions of grams.

Zipline’s drones are modular. When an order comes in, technicians snap together the three main components: the lightweight foam chassis [1], the wings [2], and the battery unit [3], which also contains the flight plan. Scanning QR codes [4] initiates automatic preflight tests of the drone’s systems. To keep the drone flying in the event of a minor mechanical failure, it has two motors [5] and redundant ailerons [6] on the wings that help maintain flight control. The drone’s cargo compartment [7] contains the package of blood until it’s parachuted down to the delivery site.

To obviate the need for a lengthy runway for takeoffs and landings, an electric catapult launches the drone, and a wire strung between towers captures the returning drone by snagging a 3-centimeter metal hook [8] on the drone’s tail.

The current Zipline battery is a combination of precision engineering and handmade charm. To make one battery, a technician puts 144 separate lithium-ion cells—each only slightly larger than an AA battery—into slots in the battery case, epoxies them by hand, and wires them together. “It feels halfway between hobby construction and an assembly line,” says Newhouse. The batteries were first assembled on-site in Rwanda, but are now shipping straight from California.

Zipline’s next-generation battery, currently in development, will be much easier to assemble, with cells that slip into prefabricated plates and get spot-welded into place. Yet the company can’t seem to stop reexamining, reconsidering, and refining its designs. “Watt-hours per kilo,” says Newhouse, referring to the essential metric driving the company’s battery design process. “That’s what’s going to make or break your system.”

Despite the intense focus on keeping the drone’s weight down, today’s Zips can carry a payload of only 1.3 kilograms. “Right now, with this generation, we can deliver two units of blood,” with some capacity to spare, says Eric Watson, a systems engineer at Zipline. The remodeled Zip that the company is currently working on will have a lighter chassis, a more efficient battery, and a payload of 1.75 kg, enabling a single drone to carry up to three units of blood at a time. It will also have a receiver for transponder signals from other aircraft, a backup communication system that uses a satellite link, and onboard sense-and-avoid equipment that will, Watson says, “be able to detect and avoid uncooperative aircraft in our airspace.” This advanced feature will likely become a safety-critical system for delivery drones as the skies get more crowded.

While the technology involved in drone delivery is impressive, the economics are more uncertain. Experts say Zipline’s high-tech solution for blood delivery is a new twist on an old story. “Go to any hospital in Africa and you’ll find a graveyard of machines,” says Jonathan Ledgard, who was the Afrotech director at the École Polytechnique Fédérale de Lausanne, in Switzerland, until 2016. “The whole history of Africa is medical equipment that was too expensive.”

Ledgard notes that Zipline currently receives subsidies from the Rwandan government to make its service affordable for hospitals. He suggests the company may be in trouble if those subsidies end. “The price points they have to charge once the subsidies end are far, far, far too high for developing countries,” Ledgard says.

Covering a Country:

Zipline’s drones can fly to hospitals up to 80 kilometers away along predetermined routes, allowing two distribution sites to cover nearly all of Rwanda.

Zipline is reluctant to disclose how much its Rwandan fulfillment centers cost to operate or how much it gets paid by the Rwandan government per delivery. The company has admitted that routine blood deliveries by drone are currently more expensive than routine deliveries by ground vehicle, which move more blood per load. But Zipline argues that the economics change in emergencies.

As Zipline seeks to expand its delivery services to more African countries, cost and sustainability are becoming central topics of discussion. Its first expansion effort, in Tanzania in 2018, fell through during contract negotiations with the government. But at the end of 2018, the government of Ghana approved a four-year contract [PDF] to deliver blood and other medical supplies by drone, worth an estimated US $12.5 million for Zipline.

The plan for Ghana calls for four fulfillment centers that will make between 100 and 150 deliveries per day. The Ghanaian government estimates a per-delivery cost of $17. Both the minority party in the country’s parliament and the Ghana Health Service criticized the contract as being too expensive, arguing that funds could be better spent elsewhere. Nevertheless, the contract was approved, and Zipline has already begun making deliveries from its first distribution center in the country.

Over the long term, Zipline argues that minimizing waste in the medical system will help the drones pay for themselves. In Rwanda, the cost to collect, test, and store a unit of blood is about $80. Before Zipline came along, about 7 percent of blood packs expired without being used, costing the Rwandan government more than $1 million annually. In 2018, the hospitals that Zipline serves wasted no blood packs at all.

Ledgard says Zipline may find a business model that works—but only for lifesaving medical deliveries. He says the current drones can’t compete with motorbikes, which can carry about 15 kg, for routine deliveries. “Until you get to 6 or more likely 12 kg [for drones], it’s not viable,” Ledgard says. Yet he gives Zipline credit for getting a delivery-drone company off the ground. “They’ve done what people like me have been talking about,” he says. “I take my hat off to them.”

As of press time, Zipline’s drones have flown a total of over 1 million km. As Zipline scales up its operations, it will likely clock its next million kilometers in under six months. In addition to its expansion into Ghana, Zipline is also part of a pilot program run by the U.S. Federal Aviation Administration, which will test medical deliveries in rural areas of North Carolina later this year.

The Rwandan government recently awarded Zipline a new, three-year contract, which includes provisions for delivering other medical products beside blood, such as medicine and vaccines. That service expansion means that Zips will soon be making drops to many small clinics, not only to hospitals. Zipline is also planning to assemble its drones in Rwanda rather than importing them from the United States. Clearly, Zipline is in Rwanda to stay.

It’s getting dark at Zipline’s Muhanga nest as we pack our bags and get ready for the long, winding drive back to Kigali. Red landing lights turn on along the approach path that the Zips follow—the drones don’t need the lights, but they look cool. In the distance, we can hear the faint buzz of another Zip returning home after making its delivery of blood. Anywhere else on Earth, it would be futuristic. In rural Rwanda, it’s just routine.

This article appears in the May 2019 print issue as “The Blood Is Here.”